Production

Processing

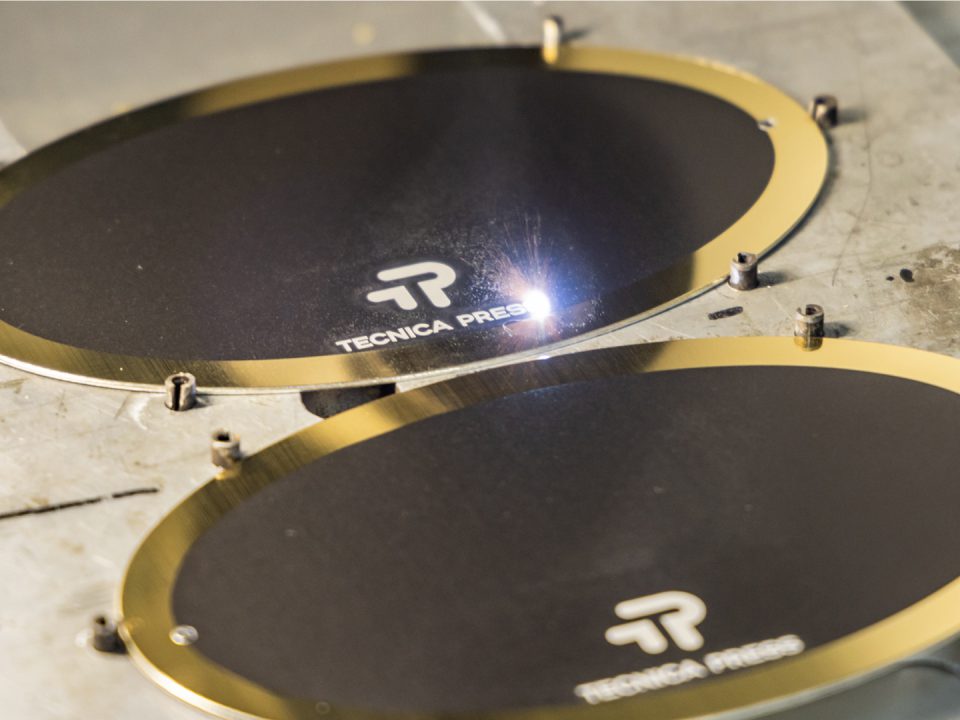

Tecnica Press can boast total in-house management, of production and product; the experienced hands of our technicians, move on the latest equipment and facilities, for the production of extremely reliable and high quality items.

Supplies of raw materials periodically enter through the doors of our production unit and finished products come out, packaged and ready for delivery.

We carry out in-house metal casting and subsequent die-casting of parts; all finishing on the unfinished part, such as deburring and vibro finishing; surface finishing with galvanic treatments, painting and brushing; mechanical processing inherent to assembly; and finally,packaging of products and preparation of packages for shipment.

In-house production

One of the aspects most appreciated by Tecnica Press’ customers, is the knowledge that they can go directly to the people who design and produce their items; without going through intermediaries and having to endure vague answers and long waits.

A feature that results in tangible savings in terms of time and costs.

We firmly believe that production is the result of many processes and variables, which adding up one by one, bring value to what will be the final product. In this regard, Tecnica Press supervises its production lines with maniacal attention, expertly organizing personnel and machinery, and always providing customers with direct service and support of the highest standard.

Since the founding of our company, manufacturing has always been the backbone, supporting its steady growth.

Thanks to our experience in the field of manufacturing, we have been able to develop a structure for process control management that is as robust as it is flexible, so that we can meet both low-volume production of very diverse items and large orders, while always maintaining, full control over supply chains. None of this would have been possible, without a series of forward-looking, long-term investments aimed at renovating facilities and technologies, with state-of-the-art systems.

Unlike other competing companies that import from abroad or contract out the manufacture of their products to third parties, Tecnica Press has decided to maintain production in-house and 100% Made in Italy for all die-cast items, a considerable amount when you consider that these account for over 90% of our catalog.

In-house production has undoubted advantages, such as direct quality control, which thus allows us to immediately intercept any problems and solve them instantly. It is also a guarantee of a continuous flow of knowledge, resulting in learning and experiential growth for our company: invaluable know-how to use on process and product improvement.

While 100 percent of die-cast products are handled in-house by Tecnica Press, the manufacture of tools, instrumentation, small parts and ancillary products, on the other hand, is the result of a precise balance between in-house production and outsourcing, achieved through long-standing partnerships with a network of trusted suppliers throughout Italy.

Richiedi informazioni

Compila il form di contatto per ottenere informazioni sui nostri servizi e richiedere un preventivo gratuito.